| PRODUCTS...Contact us now! 083 287 2026 .. stadenpompe@lantic.net .. 083 287 2026 | ||

STADEN SYSTEM | CONVENTIONAL SYSTEM | ||

| Consists of 8 components (gripper, cylinder, force head, base plate , 2 springs, rod, pipe and rope | |||

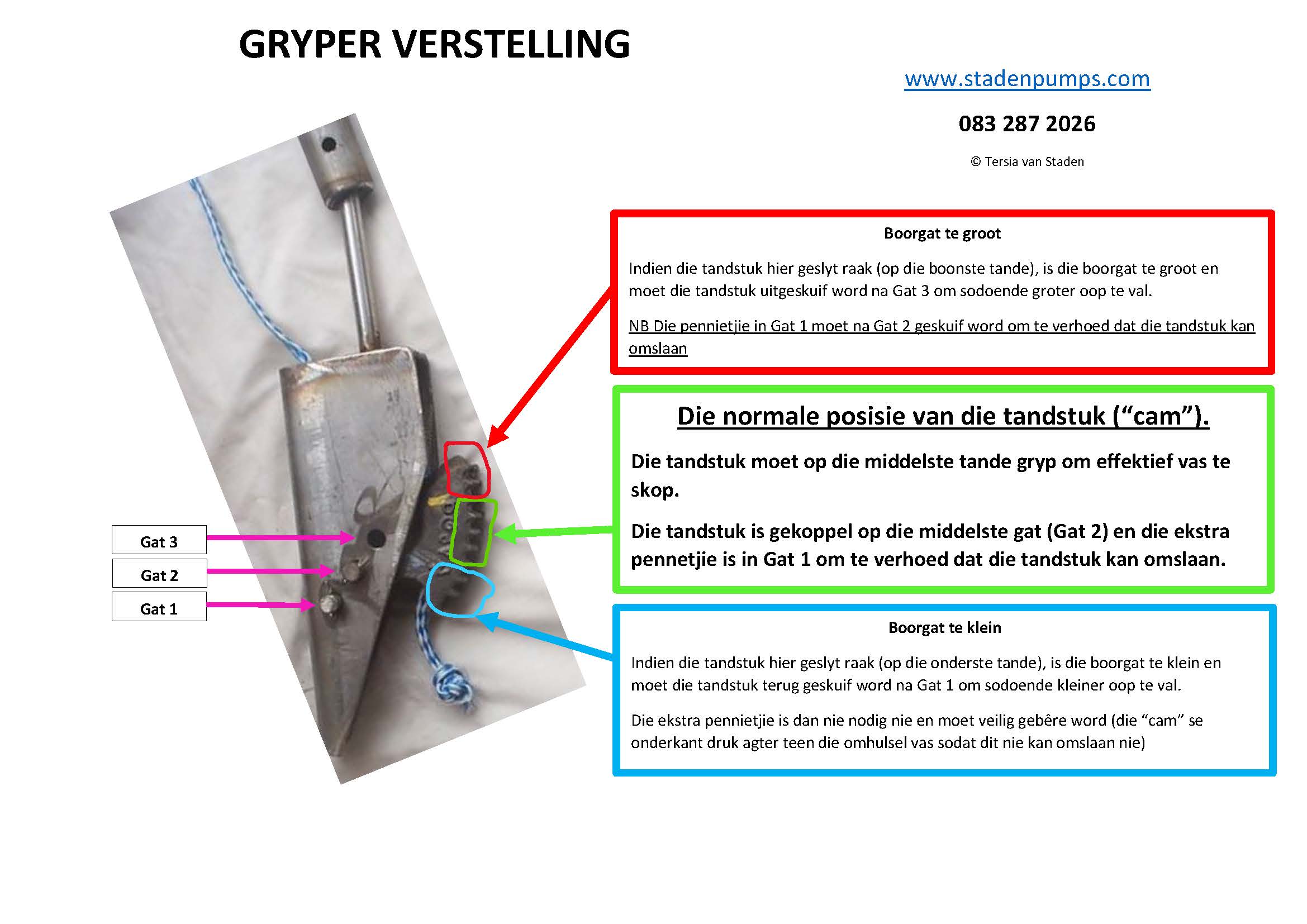

Gripper – is used to anchor the system at the bottom of the borehole. Entirely manufactured of stainless steel, with cast iron cam. Consists of a housing in which the cam moves up and down. Is activated by a 10mm ski-rope. Points to the bottom – twofold purpose – to cut off existing roots in the borehole as well as serving as a guide should the rope break. |  | ||

Cylinder – Only available in 2.5" size. Barrel and end caps are made of glass reinforced nylon, which has been polished on the inside before use. Shaft, nuts, springwashers, |  | ||

| Male adaptor – 32mm x1½" so that it can be screwed into the cylinder and fit over the pipe | |||

| Pipe – 32mm class 10 HDPE |  | ||

| Spring loaded wire – flexible to roll up ± 1.6m in diameter – if bent too much – can snap and lose spring load and damage outside pipe. Is protected by a 16 class 16 pipe and filled with grease. Sealed on both ends with a stainless steel crimp. Ends are flattened , to ensure that the shaft does not pull back - fits into a 16mm class 16 HDPE pipe. Standard 12mm female thread on both sides to fit shafts of the cylinder or force head. | |||

| Rope – 10mm ski-rope is used to activate the gripper / to deactivate – it is fastenend to the gripper and base plate. Furthermore hangs loose in the hole. |  | ||

| T-piece – 32 x 1" Female T – join the pipe in the hole with pipe from force head - O’rings. | |||

| Base plate – manufactured of stainless steel – used to ensure that no horizontal movement occurs in the system. Has a nut underneath where the rope is fastened to. More.. |  | ||

| Force head – consists of a stainless steel shaft with a lock nut , 2 x 1" leather with bushes.. Pipe serves as tubing – 32 class 16 PVC pipe. Eyenut at the top of the shaft is connected to the wooden shaft by a chain.(6,3mm) - no downward motion. More.. |  | ||

Springs – Springs are fastened with wire to the eyenut of the forcehead. Must remain taut – anchored to the cement block or lengthened with wire and anchored to the strut of the tower. Helps to pull down the shaft – more springs necessary should the water be a distance away or pumped to a higher level. |  | ||

| 0 – 6km flat surface | |||

Cement block - 40m height if hole is not deeper than 60m. | |||

| HOME ..|.. PRODUCTS ..|GALLERY ..| .. D.I.Y ..|.. CONTACT ..|.. AFRIKAANS | Design by WebworxX.co.za | ||